Blog

- Home

- /

- Blog

2025-06-03T15:29:54.000000Z

By : company

The Role of Global Standards in Ensuring Safe and Efficient Precast Concrete Structures

Global standards play a vital role in guaranteeing the safety, quality, and efficiency of precast concrete structures across diverse construction projects. This article explores how international codes and guidelines—from ACI, Eurocode, to regional standards—help engineers design, manufacture, and execute precast elements that meet stringent performance and safety requirements. Learn how adherence to these standards drives innovation while minimizing risks in precast concrete construction worldwide.

2025-06-03T15:27:26.000000Z

By : company

Mix Mastery: How Concrete Proportions Influence the Strength and Longevity of Precast Elements

The performance of precast concrete hinges on the precise balance of its mix proportions. This article delves into the science of concrete mix design, examining how factors like water-to-cement ratio, aggregate size, and additives directly affect the strength, durability, and shrinkage behavior of precast elements. Discover how mastering these mix variables leads to higher-quality, longer-lasting precast components tailored for demanding structural applications.

2025-06-03T15:25:50.000000Z

By : company

Avoiding Pitfalls: Identifying and Preventing Common Issues in Precast Concrete Systems

Precast concrete offers unmatched efficiency but can face challenges if common issues go unnoticed. This practical guide helps engineers and contractors identify typical defects like cracking, spalling, and joint failures, and presents proven prevention strategies including proper design, curing, and handling techniques. Learn how to enhance the durability and safety of precast systems by avoiding these pitfalls early in the construction process.

2025-06-03T15:13:20.000000Z

By : company

Essential Tests for Precast Concrete Before and After Casting

Quality assurance in precast concrete starts long before installation. This article outlines the critical tests conducted before and after casting, such as the slump test, compressive strength test, and non-destructive testing (NDT) methods. Learn how these procedures help verify workability, strength, and durability, ensuring precast components meet structural standards and performance expectations in real-world conditions.

2025-06-03T15:06:06.000000Z

By : company

Applications of Precast Concrete in High-Rise Buildings and Bridges

Precast concrete is revolutionizing large-scale construction through faster timelines and enhanced precision. This article explores how precast elements—such as beams, columns, wall panels, and bridge segments—are effectively used in high-rise buildings and infrastructure projects. Featuring real-world case studies, we highlight the engineering benefits, modular coordination, and logistical advantages of using precast in vertical and horizontal structures.

2025-06-03T15:03:54.000000Z

By : company

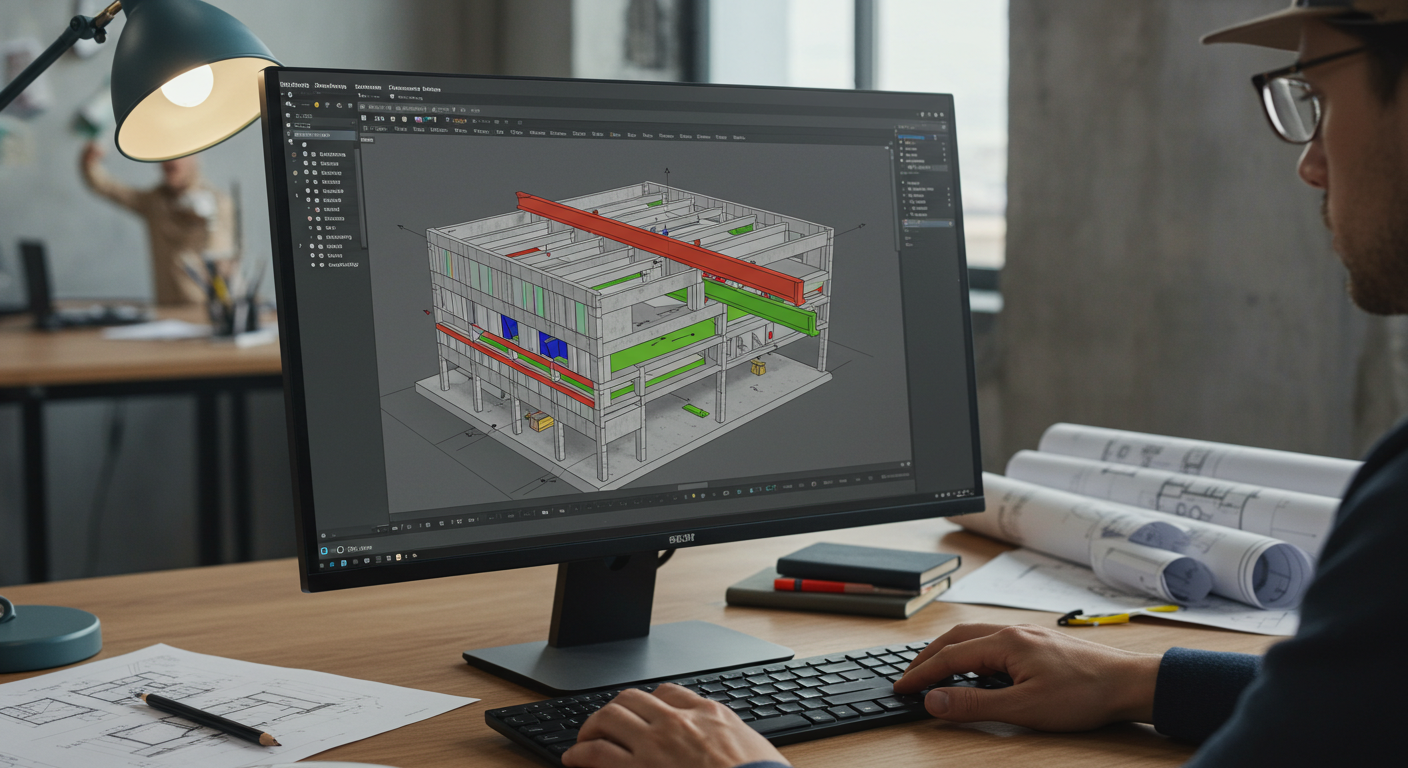

Role of Structural Software in Modeling Precast Concrete Systems

Modern precast construction demands precision, and structural software plays a vital role in achieving it. This article explores how leading tools like ETABS, SAP2000, and Autodesk Revit enhance the modeling, structural analysis, and detailing of precast concrete systems. From load simulation to connection design and BIM integration, learn how these platforms support efficient, code-compliant precast projects from concept to construction.

2025-06-03T14:55:50.000000Z

By : company

Structural Considerations During Transport and Erection of Precast Elements

Transporting and erecting precast concrete components presents unique engineering challenges that must be addressed to ensure structural integrity and site safety. This article explores the critical considerations involved in lifting, handling, transporting, and installing precast elements, focusing on stress management, support conditions, and stability during temporary stages. Learn how to mitigate risks through proper design detailing, rigging techniques, and adherence to safety standards during each phase of precast construction.

2025-06-03T14:53:25.000000Z

By : company

Designing Structural Elements Using Precast Concrete: Engineering Best Practices

As the construction industry increasingly turns to off-site fabrication and modular building techniques, precast concrete has become a preferred material for engineers and designers seeking speed, precision, and durability. This in-depth blog post provides an engineering-focused guide on how to design critical structural elements—including beams, columns, and slabs—using precast concrete components in accordance with international structural design codes (such as ACI, Eurocode, and BS standards). Through a practical and technical lens, we break down the design principles, load considerations, reinforcement detailing, connection strategies, and tolerance specifications needed to ensure safe and efficient precast construction. Whether you're working on a commercial tower, residential complex, or infrastructure facility, this guide helps structural engineers achieve optimal design efficiency and compliance with safety standards. Key topics covered include: Structural design of precast beams (simply supported, continuous, and prestressed) Column sizing, reinforcement anchorage, and load transfer in precast frames Design of precast floor slabs and hollow-core systems Connection detailing for lateral load resistance Considerations for seismic zones and differential settlement Coordination between design, production, and erection phases Packed with technical examples and code references, this article is a must-read resource for structural engineers, architects, and precast manufacturers aiming to build safe, code-compliant, and time-efficient structures.

2024-11-25T13:19:32.000000Z

By : company

Precast Concrete: The Future of Fast and Accurate Construction

In today’s fast-paced construction industry, precast concrete has emerged as a game-changing solution for developers, architects, and contractors seeking efficiency, precision, and cost savings. This in-depth blog post explores how precast concrete technology is redefining modern construction by enabling faster project delivery, high-quality finishes, and superior structural integrity compared to traditional on-site casting methods. We dive deep into the core benefits of precast concrete—such as reduced labor costs, minimal on-site disruption, enhanced durability, and environmental sustainability. You’ll also learn about the most common applications of precast systems in commercial buildings, bridges, infrastructure, and residential developments. From manufacturing in a controlled environment to precision installation on site, precast concrete offers unmatched consistency and reliability. Whether you’re planning a small development or a large-scale infrastructure project, this article will help you understand why precast concrete is the preferred choice for future-ready construction. Boost your project's success by exploring how precast concrete improves construction timelines, reduces waste, and aligns with green building standards. Don’t miss out on this comprehensive guide to one of the construction industry’s most transformative technologies.

2024-11-25T12:32:33.000000Z

By : company

Precast vs Cast-in-Place Concrete: An Engineering Comparison

When it comes to modern structural engineering and construction, choosing between precast concrete and cast-in-place concrete can significantly influence project outcomes. This blog post presents a comprehensive engineering comparison between these two widely used concrete methods, examining critical factors such as structural strength, quality control, construction speed, site logistics, and long-term performance. We explore how precast concrete, manufactured off-site in a controlled environment, offers precision, durability, and faster installation, while cast-in-place concrete provides on-site flexibility, custom shapes, and continuous structural integrity. Through real-world case studies and engineering insights, this article helps builders, architects, and civil engineers determine which method best suits their project needs—whether it's a commercial high-rise, infrastructure bridge, or residential foundation. You’ll gain a clear understanding of: Load-bearing capabilities Crack resistance and shrinkage behavior Site preparation and labor demands Project timelines and weather sensitivity Cost considerations and material efficiency Whether you’re working in urban development, transport infrastructure, or industrial facilities, this detailed analysis will help you make informed decisions about which concrete construction method is most efficient, practical, and cost-effective.